Peb siv cov mis tsis muaj dysprosium ntawm cov khoom siv qis qis rau cov neeg siv khoom kom txo cov nqi.Peb muaj cov qauv ruaj khov uas tuaj yeem ua rau cov khoom tsis tshua muaj kub coefficient.Nws txo cov nqi thiab ua kom muaj txiaj ntsig ntxiv rau cov neeg siv khoom nrog nruj tswj kev ua siab ntev hauv kev ua thiab txheej txheej raws li cov neeg siv khoom sib txawv kom ntseeg tau tias kev ruaj ntseg ntawm plating tiv thaiv tib lub sijhawm, suav nrog ntsev tsuag, txheej khi quab yuam, colloid affinity thiab lwm yam. .

Round khoom yog nquag mus rau cov ces kaum uas ploj lawm hauv cov txheej txheem ntau lawm.Yog li peb muaj cov cuab yeej tshuaj xyuas tsis siv neeg tag nrho rau qhov pom kev pom zoo, uas tuaj yeem ua kom cov khoom tsis xws luag hauv kev tswj tau ntau yam thiab zam cov khoom puas hauv kev siv cov txheej txheem.

Nyob rau hauv cov nqe lus ntawm flux sib xws, peb xyuas kom meej-taw tes sintering rauv rau qhov sib xws ntawm cov txheej txheem hlau nplaum tswj, thiab sib nqus flux tag nrho cov cuab yeej tshuaj xyuas los tiv thaiv cov khoom tsis muaj zog sib nqus los ntawm cov neeg siv khoom.Nyob rau hauv cov nqe lus ntawm magnetization ntim, peb lub tuam txhab muaj taug qab tsis siv neeg coding magnetization khoom los tiv thaiv cov neeg ua hauj lwm los ntawm mischarging cov hlau nplaum.

Nyob rau hauv cov nqe lus ntawm kev tswj tus me nyuam, ib tug loj tus naj npawb ntawm multi-line txiav tshuab, slicing units, mature technical processing neeg ua hauj lwm, zoo meej cov txheej txheem kev soj ntsuam xyuas, txhua kauj ruam ntawm cov khoom ua thiab ntau lawm yuav tau txais kev vam meej tswv yim txhua lub sij hawm, mature cylindrical khoom ntau lawm kab, los xyuas kom meej cov neeg siv khoom tswj cov kev xav tau ntawm cov khoom xa tuaj, nrog rau kev tswj hwm kev ua tiav.

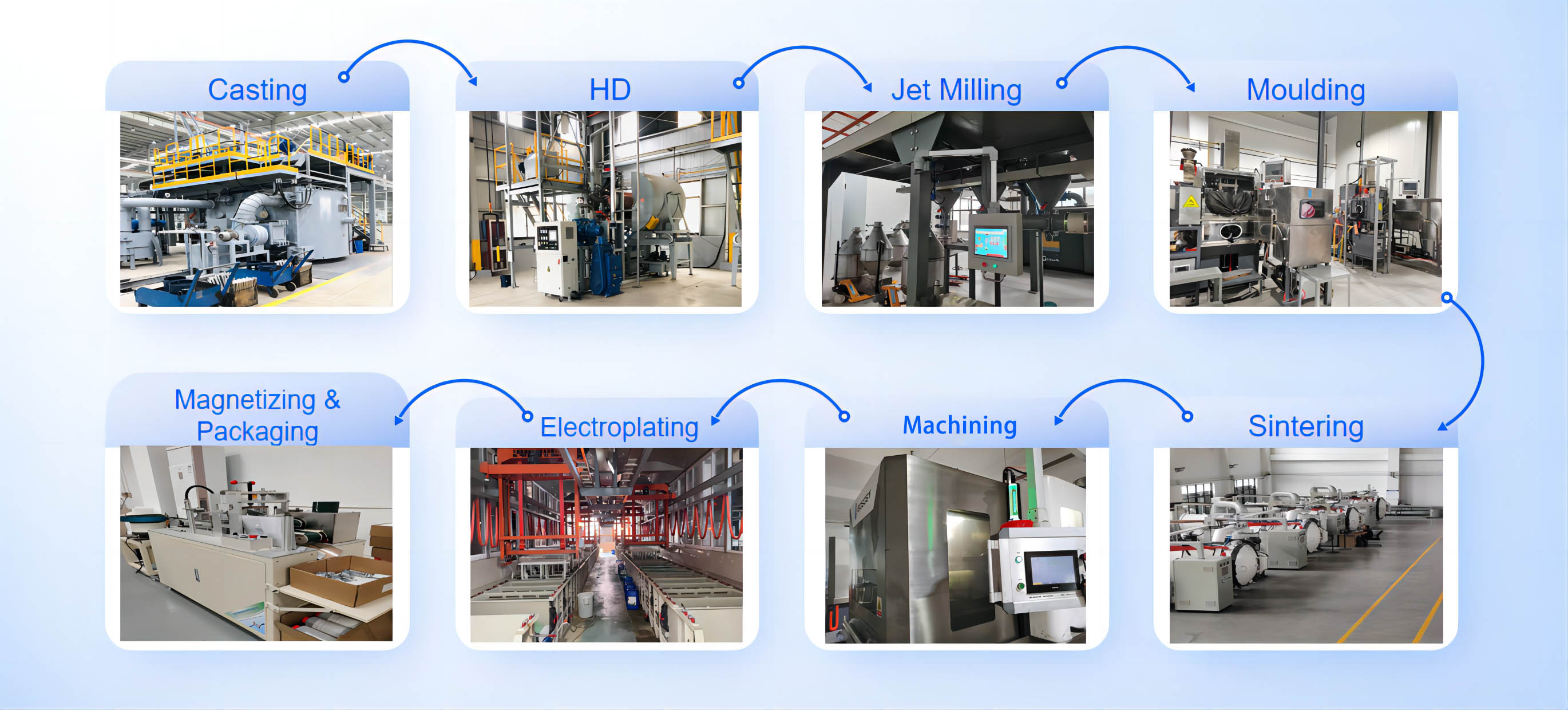

NdFeB Production Process

Txheej Taw Qhia

| Nto | Txheej | Thickness μm | Xim | SST Sijhawm | PCT Sijhawm | |

| Nickel | Ni | 10 ~ 20 | Bright Silver | > 24-72 | > 24-72 | |

| Ni+Cu+Ni | ||||||

| Dub Nickel | Ni+Cu+Ni | 10 ~ 20 | Xim dub | > 48-96 | > 48 | |

| Cr3 + Zinc | Zn C-Zn | 5 x8 | Brighe Blue Xim Xim | > 16-48 > 36-72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 ~ 25 | Nyiaj | > 36-72 | > 48 | |

| Au | Ni+Cu+Ni+Au | 10 ~ 15 | Kub | > 12 | > 48 | |

| Ag | Ni+Cu+Ni+Ag | 10 ~ 15 | Nyiaj | > 12 | > 48 | |

| Epoxy | Epoxy | 10 ~ 20 | Dub / Grey | > 48 | --- | |

| Ni + Cu + Epoxy | 15-30 Nws | > 72–108 | --- | |||

| Zn + Epoxy | 15 ~ 25 | > 72–108 | --- | |||

| Passivation | --- | 1 x3 | Tsaus Grey | Kev tiv thaiv ib ntus | --- | |

| Phosphate | --- | 1 x3 | Tsaus Grey | Kev tiv thaiv ib ntus) | --- | |

Cov yam ntxwv ntawm lub cev

| Yam khoom | Tsis muaj | Siv tus nqi | Chav tsev |

| Sib Nqus Sib Nqus Cov khoom | Reversible Temperature Coefficient Ntawm Br | -0.08 - 0.12 | % / ℃ |

| Reversible Temperature Coefficient Ntawm Hcj | -0.42~-0.70 | % / ℃ | |

| Tshwj xeeb kub | 0.502 ib | KJ·(Kg· ℃)-1 | |

| Curie Kub | 310-380 : kuv | ℃ | |

| Mechanical Physical Cov khoom | Qhov ntom | 7.5-7.80 Nws | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Hluav taws xob Resistance | 1.4x10-6 | μQ os | |

| Compressive zog | 1050 | MPa | |

| Tensile zog | 80 | Mpa | |

| Khoov zog | 290 | Mpa | |

| Thermal conductivity | 6: 8,95 | W/m · K | |

| Young's Modulus | 160 | GPa | |

| Thermal Expansion (C⊥) | -1.5 | 10-6 ℃ -1 | |

| Thermal Expansion (CII) | 6.5 | 10-6 ℃ -1 |

Daim duab Display