Rau qhov loj me, peb lub tuam txhab tau nruab nrog arc loj sorting tshuab ntawm Keyence, uas txo qhov kev pheej hmoo los ntawm kev phem batch ntawm kev kam rau siab tswj kev sib dhos ib feem hlau nplaum sib dhos ntawm cov neeg siv khoom.

Tsis muaj teeb meem dab tsi ntawm txheej txheej, peb txhua tus tuaj yeem ua kom muaj kev kho tshwj xeeb ntawm arc ntawm ntu rau colloid affinity ntawm hlau nplaum rau cov kev daws teeb meem hauv cov txheej txheem siv qhov twg cov nplaum, cov nplaum nplaum nplaum tsis txaus thiab lwm yam.

Rau cov nqe lus xa khoom, peb muaj ntau qhov sib txawv hauv qhov ntau thiab tsawg thiab qib, rau kev ua qauv hlau nplaum txhua lub sijhawm.Peb xaj hmoov ua ntej ua ntej kom yoog raws dual alloy thev naus laus zis tuaj yeem ua tiav cov neeg siv khoom xa tuaj tom qab tau txais cov neeg siv khoom xav tau.

Peb lub tuam txhab tau nruab nrog cov kws tshaj lij thiab pab pawg muag khoom uas tuaj yeem muab cov lus qhia tswv yim, cov phiaj xwm hlau nplaum sib dhos, thiab cov neeg siv ntau lub sijhawm los xyuas kom meej tias tsis muaj kev txhawj xeeb ntxiv hauv cov txheej txheem siv rau cov neeg siv khoom.

Peb nruj me ntsis ua raws li cov txheej txheem ntawm kev tswj cov txheej txheem, kev tswj cov dej ntws raws li IATF16949 system, kom ntseeg tau tias kev xa khoom thiab kev saib xyuas zoo rau cov neeg siv khoom.

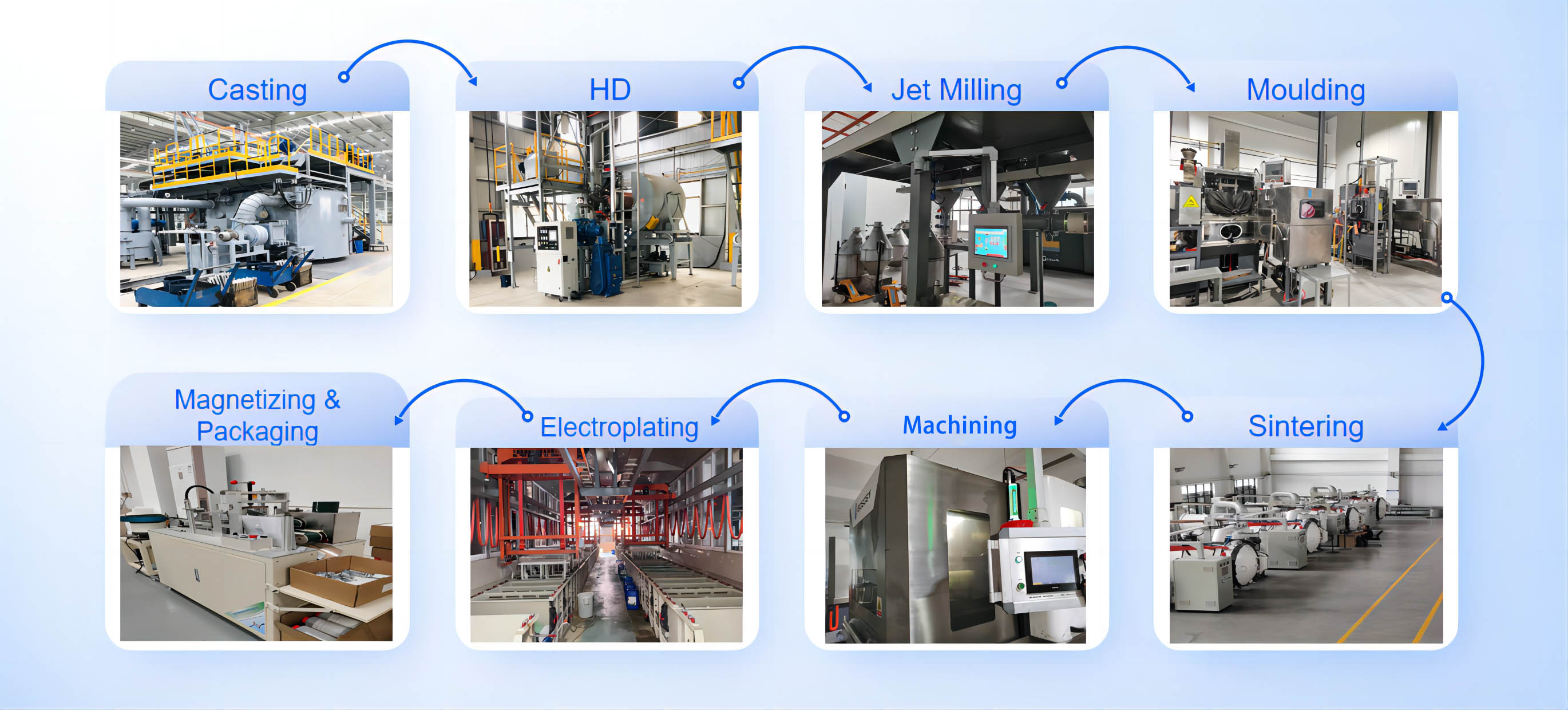

NdFeB Production Process

Txheej Taw Qhia

| Nto | Txheej | Thickness μm | Xim | SST Sijhawm | PCT Sijhawm | |

| Nickel | Ni | 10 ~ 20 | Bright Silver | > 24-72 | > 24-72 | |

| Ni+Cu+Ni | ||||||

| Dub Nickel | Ni+Cu+Ni | 10 ~ 20 | Xim dub | > 48-96 | > 48 | |

| Cr3 + Zinc | Zn C-Zn | 5 x8 | Brighe Blue Xim Xim | > 16-48 > 36-72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 ~ 25 | Nyiaj | > 36-72 | > 48 | |

| Au | Ni+Cu+Ni+Au | 10 ~ 15 | Kub | > 12 | > 48 | |

| Ag | Ni+Cu+Ni+Ag | 10 ~ 15 | Nyiaj | > 12 | > 48 | |

| Epoxy | Epoxy | 10 ~ 20 | Dub / Grey | > 48 | --- | |

| Ni + Cu + Epoxy | 15-30 Nws | > 72–108 | --- | |||

| Zn + Epoxy | 15 ~ 25 | > 72–108 | --- | |||

| Passivation | --- | 1 x3 | Tsaus Grey | Kev tiv thaiv ib ntus | --- | |

| Phosphate | --- | 1 x3 | Tsaus Grey | Kev tiv thaiv ib ntus) | --- | |

Cov yam ntxwv ntawm lub cev

| Yam khoom | Tsis muaj | Siv tus nqi | Chav tsev |

| Sib Nqus Sib Nqus Cov khoom | Reversible Temperature Coefficient Ntawm Br | -0.08 - 0.12 | % / ℃ |

| Reversible Temperature Coefficient Ntawm Hcj | -0.42~-0.70 | % / ℃ | |

| Tshwj xeeb kub | 0.502 ib | KJ·(Kg· ℃)-1 | |

| Curie Kub | 310-380 : kuv | ℃ | |

| Mechanical Physical Cov khoom | Qhov ntom | 7.5-7.80 Nws | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Hluav taws xob Resistance | 1.4x10-6 | μQ os | |

| Compressive zog | 1050 | MPa | |

| Tensile zog | 80 | Mpa | |

| Khoov zog | 290 | Mpa | |

| Thermal conductivity | 6: 8,95 | W/m · K | |

| Young's Modulus | 160 | GPa | |

| Thermal Expansion (C⊥) | -1.5 | 10-6 ℃ -1 | |

| Thermal Expansion (CII) | 6.5 | 10-6 ℃ -1 |

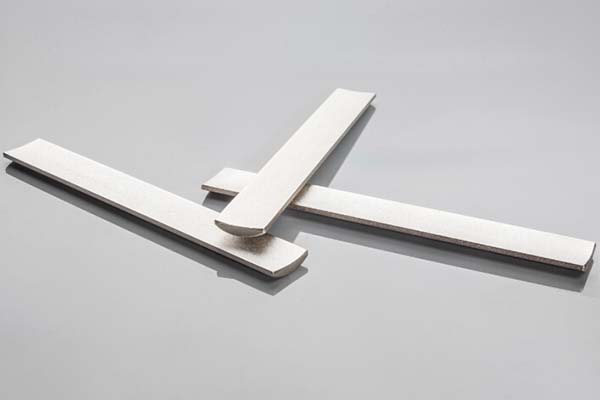

Daim duab Display