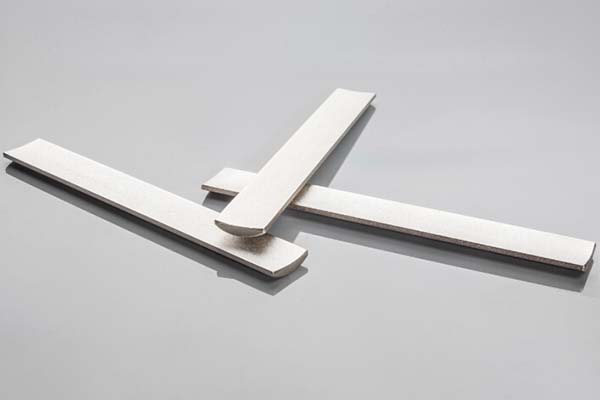

Cabbirka, shirkadeena waxay ku qalabaysan tahay mashiinka kala soocida cabbirka arc ee Keyence, taas oo yaraynaysa khatarta ay keento dufcaddii xun ee xakamaynta dulqaadka qaybta magnet-ka ee macaamiisha.

Si kasta oo ay tahay nooca daahan, dhammaanteen waxaan hubin karnaa daawaynta gaarka ah ee arc dusha sare ee qaybta loogu talagalay isku xirnaanta kolloid ee magnet si xalalka habka isticmaalka halkaas oo usha, xiisadda xabagta ee ku xiran waa mid aan ku filneyn iyo wixii la mid ah.

Shuruudaha gaarsiinta, waxaan haynaa bannaanno kala duwan oo cabbirro iyo darajooyin kala duwan leh, si loo sameeyo magnet-ka-soo-jeedka waqti kasta.Waxaan horay u dalbannaa budada budada ah si tiknoolijiyada dual alloy-ka dabacsan ay u qanciso shuruudaha gaarsiinta macaamiisha ka dib markaan helno baahida macaamiisha.

Shirkaddayadu waxay ku qalabaysan tahay koox farsamo iyo iibka xirfadlayaasha ah kuwaas oo ku siin kara talo farsamo, nidaamka isku dhafka magnet, iyo tiro badan oo ah kiisaska isticmaalka wakhti kasta si loo hubiyo in aysan jirin welwel dheeraad ah oo ku saabsan habka loo isticmaalo macaamiisha.

Waxaan si adag u hoggaansanahay heerarka xakamaynta habka, xakamaynta socodka si waafaqsan nidaamka IATF16949, si loo hubiyo bixinta iyo kormeerka tayada macaamiisha.

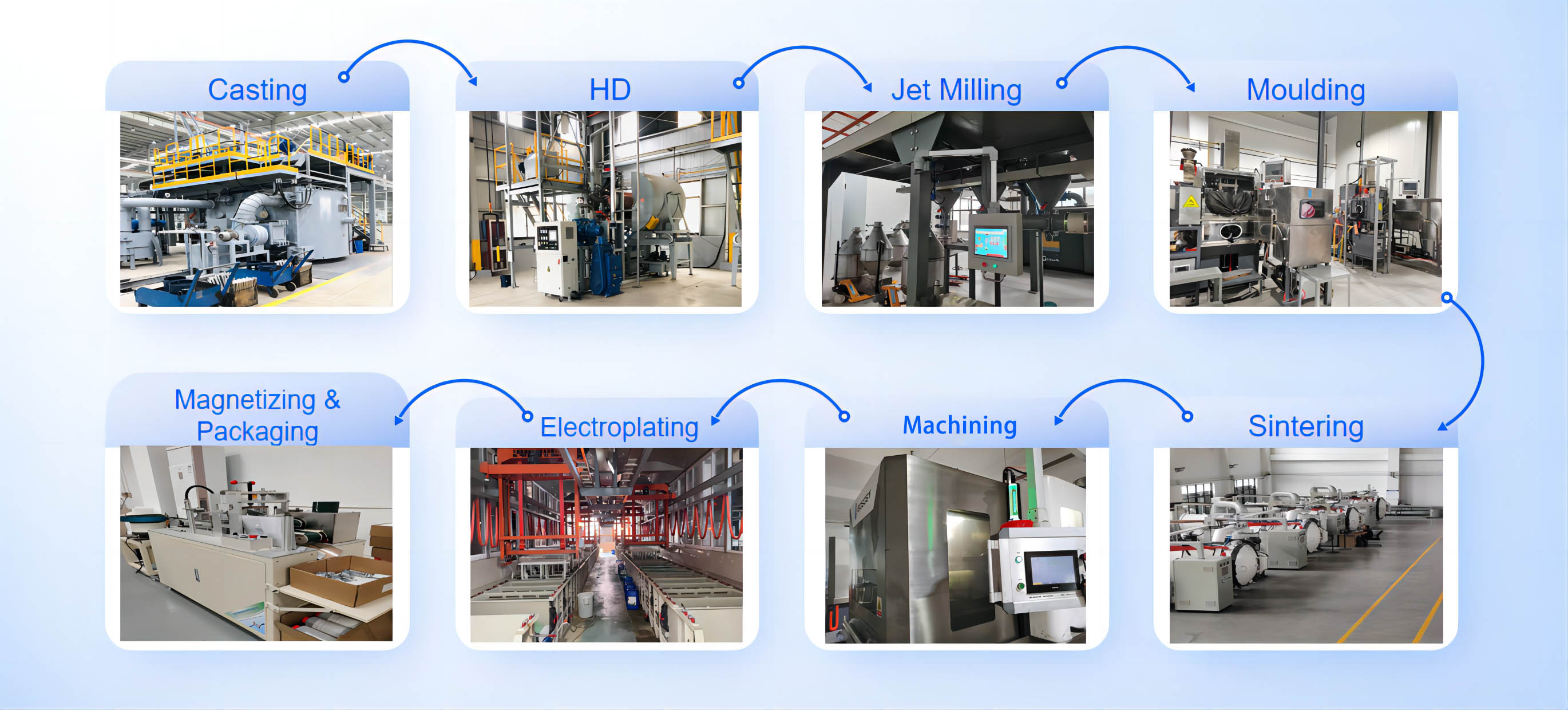

Habka Waxsoosaarka NdFeB

Hordhac Dahaarka

| Dusha sare | Dahaarka | Dhumucda μm | Midabka | Saacadaha SST | Saacadaha PCT | |

| Nikkel | Ni | 10 ilaa 20 | Silver dhalaalaya | >24~72 | >24~72 | |

| Ni+Cu+Ni | ||||||

| Nickel madow | Ni+Cu+Ni | 10 ilaa 20 | Madow dhalaalaya | >48~96 | >48 | |

| Cr3+ Zinc | Zn C-Zn | 5~8 | Brighe Blue Midabka dhalaalaya | >16~48 >36~72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 ilaa 25 | Silver | >36~72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10 ilaa 15 | Dahab | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10 ilaa 15 | Silver | >12 | >48 | |

| Epoxy | Epoxy | 10 ilaa 20 | Madow/Cawlan | >48 | --- | |

| Ni+Cu+Epoxy | 15 ilaa 30 | >72~108 | --- | |||

| Zn+Epoxy | 15 ilaa 25 | >72~108 | --- | |||

| Dareenka | --- | 1~3 | Cawlan madow | Ilaalinta ku meel gaadhka ah | --- | |

| Fosfate | --- | 1~3 | Cawlan madow | Ilaalinta ku meel gaadhka ah) | --- | |

Astaamaha Jirka

| Shayga | Halbeegyada | Tixraaca Qiimaha | Unug |

| Kaaliyaha Magnetik Guryaha | Isku-dhafka Heerkulka La-noqon karo ee Br | -0.08--0.12 | %/℃ |

| Isku-dhafka Heerkulka La-noqon karo ee Hcj | -0.42~-0.70 | %/℃ | |

| Kuleylka Gaarka ah | 0.502 | KJ · (Kg ·℃)-1 | |

| Heerkulka Curie | 310 ~ 380 | ℃ | |

| Mechanical Physical Guryaha | Cufnaanta | 7.5-7.80 | g/cm3 |

| Vickers Hardness | 650 | Hv | |

| Iska caabinta Korontada | 1.4x10-6 | μQ ·m | |

| Xoog isku dhejisan | 1050 | MPa | |

| Xoogga Jilicsan | 80 | Mpa | |

| Xoog Laabashada | 290 | Mpa | |

| Habdhaqanka kulaylka | 6 ilaa 8.95 | W/m ·K | |

| Modulka dhalinyarada | 160 | GPA | |

| Balaadhinta kulaylka (C⊥) | -1.5 | 10-6/℃-1 | |

| Balaadhinta kulaylka (CII) | 6.5 | 10-6/℃-1 |

Muujinta Sawirka