Ngobungakanani, inkampani yethu ixhotyiswe ngomatshini wokuhlela ubungakanani be-arc ye-Keyence, enciphisa umngcipheko obangelwa yibhetshi embi yolawulo lokunyamezelana inxalenye yendibano yemagnethi yabathengi.

Kungakhathaliseki ukuba luhlobo luni lokutyabeka, sonke sinokuqinisekisa unyango olukhethekileyo lwe-arc kumphezulu wecandelo le-colloid affinity yemagnethi kwizisombululo kwinkqubo yokusetyenziswa apho intonga, ukunyanzeliswa kweglue edibeneyo ayanelanga kunye nokunye.

Kwimiqathango yonikezelo, sineendawo ezingenanto ezahlukeneyo ngobukhulu kunye namabakala, ukwenza imagnethi yeprototype nangaliphi na ixesha.Siodola umgubo ngobuninzi kwangaphambili ukuze itekhnoloji ye-alloy eguquguqukayo ikwazi ukwanelisa iimfuno zokuhanjiswa kwabathengi emva kokufumana imfuno yomthengi.

Inkampani yethu ixhotyiswe ngeqela lobuchwephesha kunye neqela lokuthengisa elinokubonelela ngeengcebiso zobuchwephesha, iskimu sokudityaniswa kwemagnethi, kunye nenani elikhulu lamatyala okusebenzisa nangaliphi na ixesha ukuqinisekisa ukuba akukho maxhala ongezelelweyo kwinkqubo yokusetyenziswa kwabathengi.

Sithobela ngokungqongqo imigangatho yolawulo lwenkqubo, ulawulo lokuqukuqela ngokuhambelana nenkqubo ye-IATF16949, ukuqinisekisa ukuhanjiswa kunye nokujongwa komgangatho kubathengi.

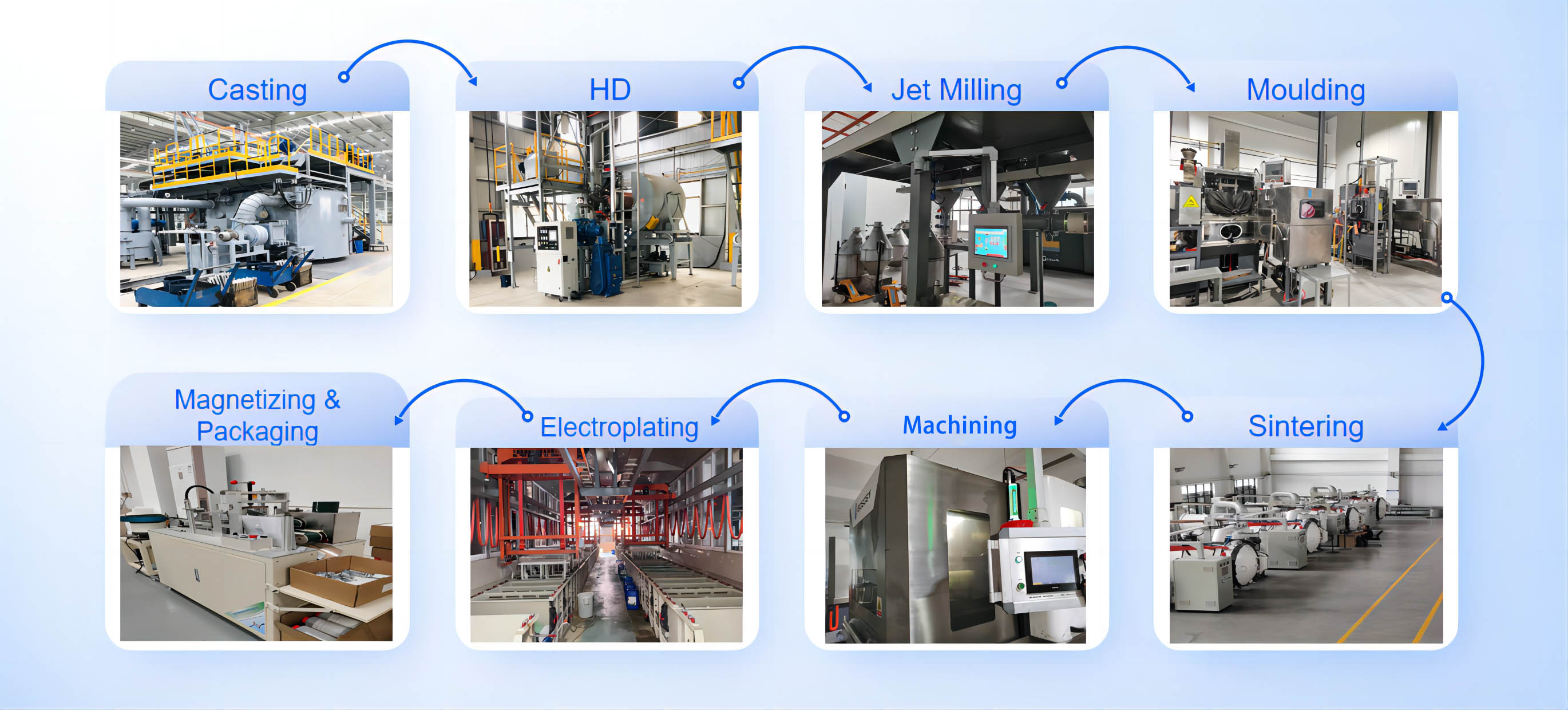

Inkqubo yeMveliso yeNdFeB

Ukwaleka Intshayelelo

| Umphezulu | Ukwaleka | Ukutyeba μm | Umbala | Iiyure ze-SST | Iiyure zePCT | |

| Nickel | Ni | 10~20 | Isilivere eqaqambileyo | >24 ukuya kutsho ku72 | >24 ukuya kutsho ku72 | |

| Ni+Cu+Ni | ||||||

| I-Nickel emnyama | Ni+Cu+Ni | 10~20 | Umnyama Oqaqambileyo | > 48-96 | >48 | |

| Cr3+Zinc | Zn C-Zn | 5 ~8 | UBrighe Blue Umbala Oqaqambileyo | >16 -48 > 36 -72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 ~ 25 | Isilivere | > 36 -72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10~15 | Igolide | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10 ~ 15 | Isilivere | >12 | >48 | |

| Epoxy | Epoxy | 10~20 | Mnyama / Grey | >48 | --- | |

| Ni+Cu+Epoxy | 15 ~ 30 | >72 ~108 | --- | |||

| Zn+Epoxy | 15 ~ 25 | >72 ~108 | --- | |||

| Ukunyamezela | --- | 1~3 | Grey emnyama | Ukhuseleko lwexeshana | --- | |

| Iphosphate | --- | 1~3 | Grey emnyama | Ukhuseleko lwexeshana) | --- | |

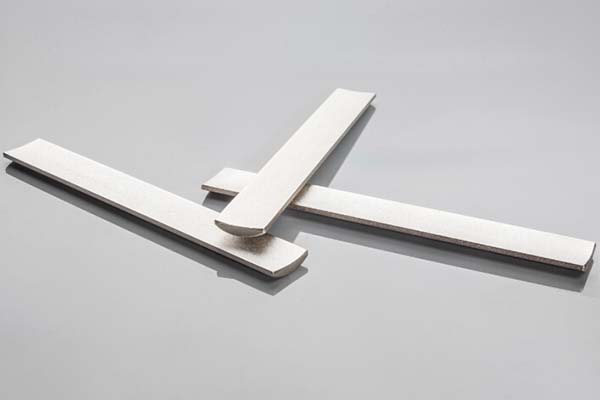

Iimpawu zoMzimba

| Into | Iiparamitha | Ixabiso leReferensi | Iyunithi |

| I-Magnetic encedisayo Iipropati | I-Coefficient yoBubushushu obubuyiselwayo ye-Br | -0.08--0.12 | %/℃ |

| I-Coefficient yoBubushushu obubuyiselwayo ye-Hcj | -0.42-0.70 | %/℃ | |

| Ubushushu obuthile | 0.502 | KJ ·(Kg ·℃)-1 | |

| Ubushushu beCurie | 310~380 | ℃ | |

| Mechanical Physical Iipropati | Ukuxinana | 7.5~7.80 | g/cm3 |

| Vickers Ukuqina | 650 | Hv | |

| Ukunyangwa koMbane | 1.4x10-6 | μQ · m | |

| Amandla acinezelayo | 1050 | MPa | |

| Tensile strength | 80 | Mpa | |

| Ukugoba Amandla | 290 | Mpa | |

| I-Thermal Conductivity | 6 ukuya ku-8.95 | W/m ·K | |

| Imodulus yolutsha | 160 | GPA | |

| Ukwandiswa kweThermal(C⊥) | -1.5 | 10-6/℃-1 | |

| Ukwandiswa kweThermal(CII) | 6.5 | 10-6/℃-1 |

Umboniso Wemifanekiso